Image 1 of 20

Image 1 of 20

Image 2 of 20

Image 2 of 20

Image 3 of 20

Image 3 of 20

Image 4 of 20

Image 4 of 20

Image 5 of 20

Image 5 of 20

Image 6 of 20

Image 6 of 20

Image 7 of 20

Image 7 of 20

Image 8 of 20

Image 8 of 20

Image 9 of 20

Image 9 of 20

Image 10 of 20

Image 10 of 20

Image 11 of 20

Image 11 of 20

Image 12 of 20

Image 12 of 20

Image 13 of 20

Image 13 of 20

Image 14 of 20

Image 14 of 20

Image 15 of 20

Image 15 of 20

Image 16 of 20

Image 16 of 20

Image 17 of 20

Image 17 of 20

Image 18 of 20

Image 18 of 20

Image 19 of 20

Image 19 of 20

Image 20 of 20

Image 20 of 20

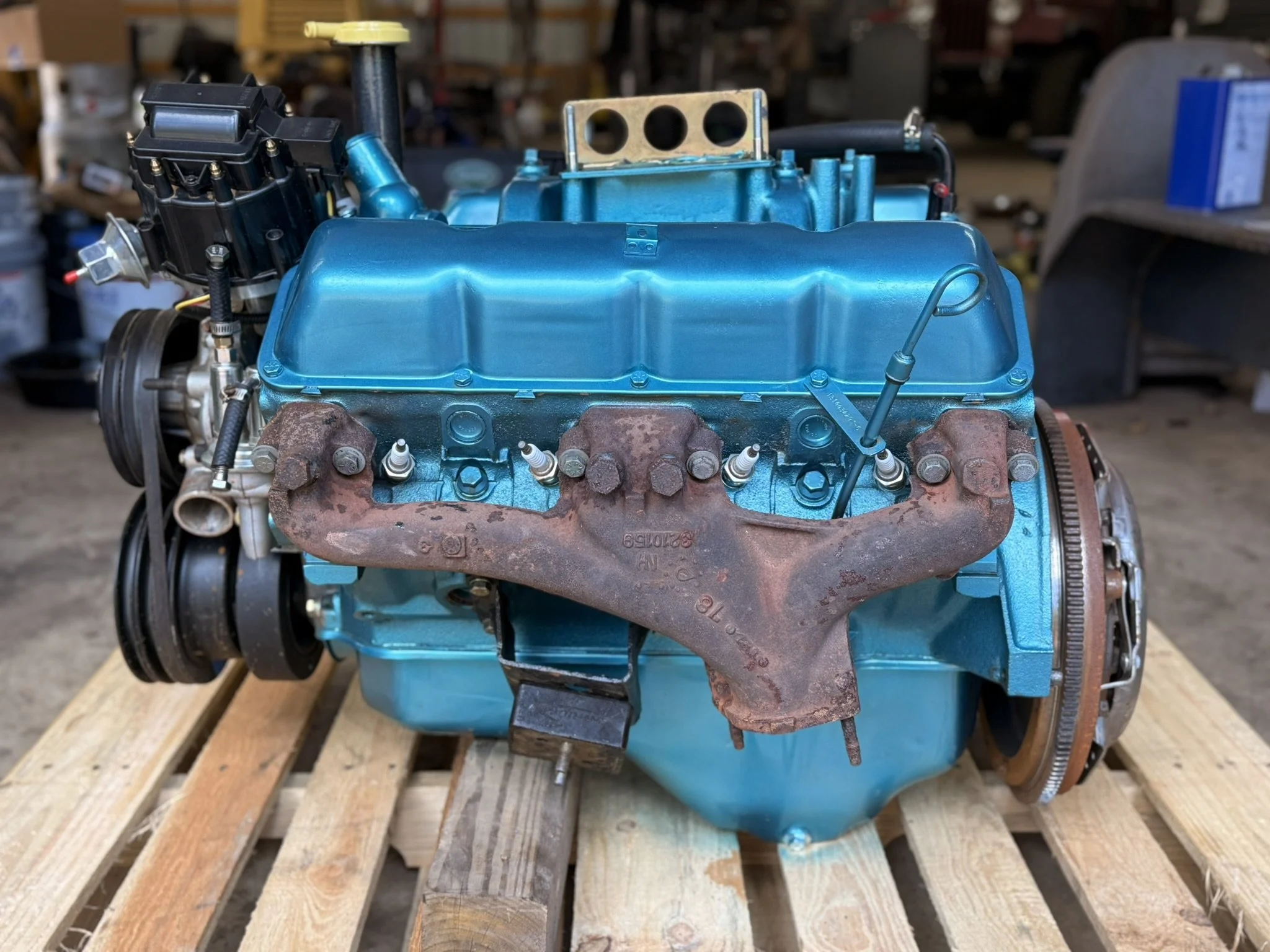

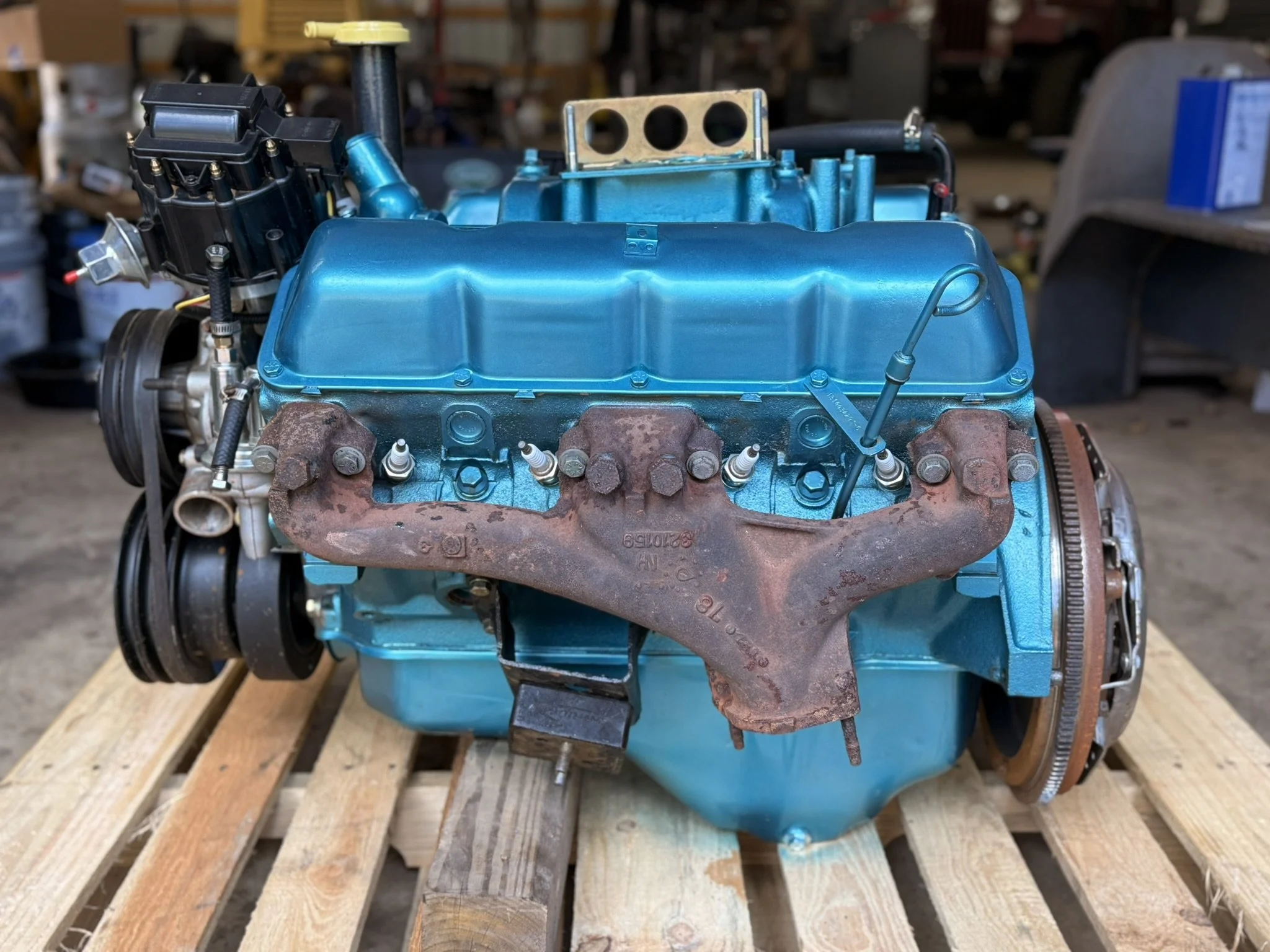

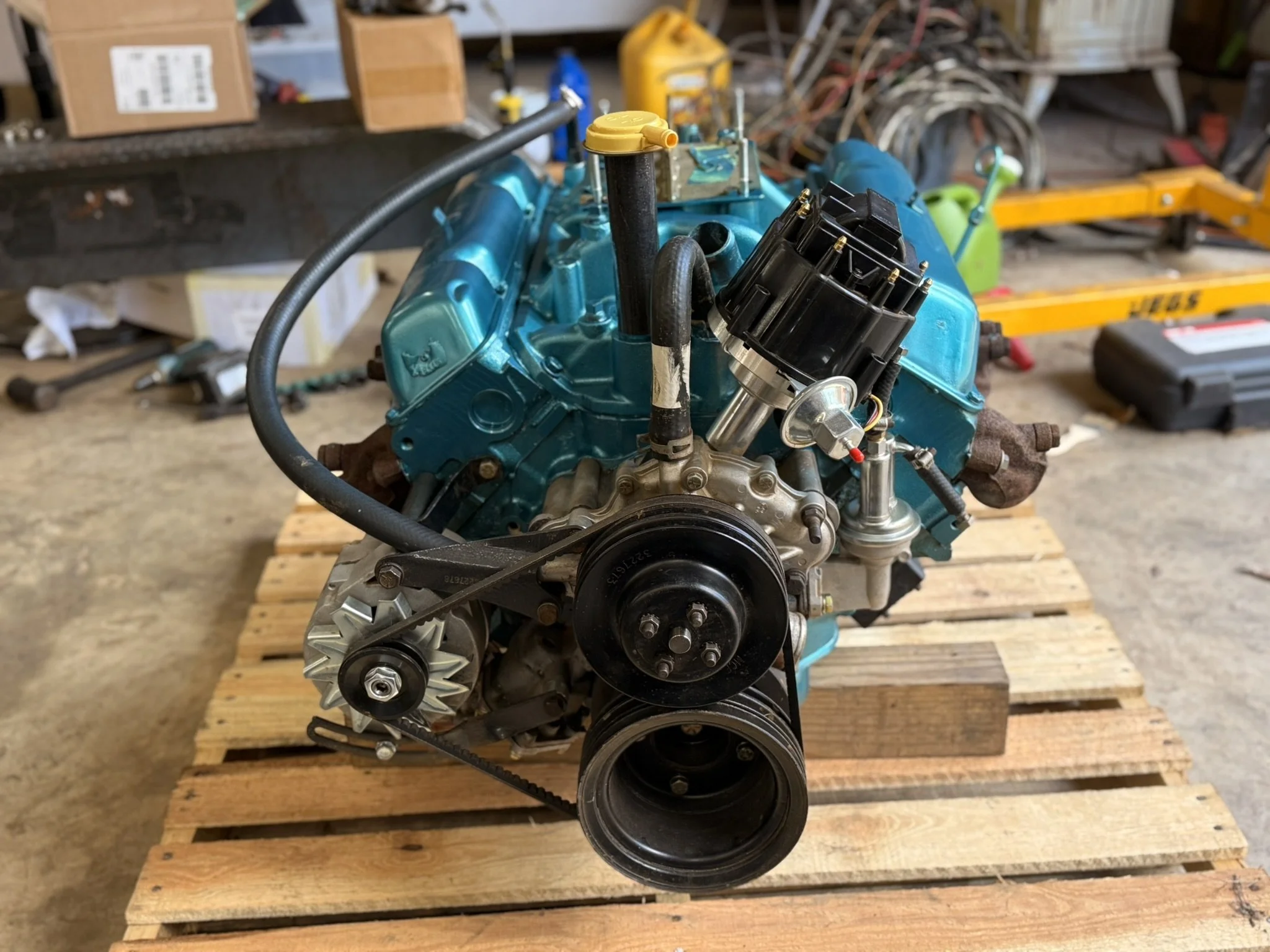

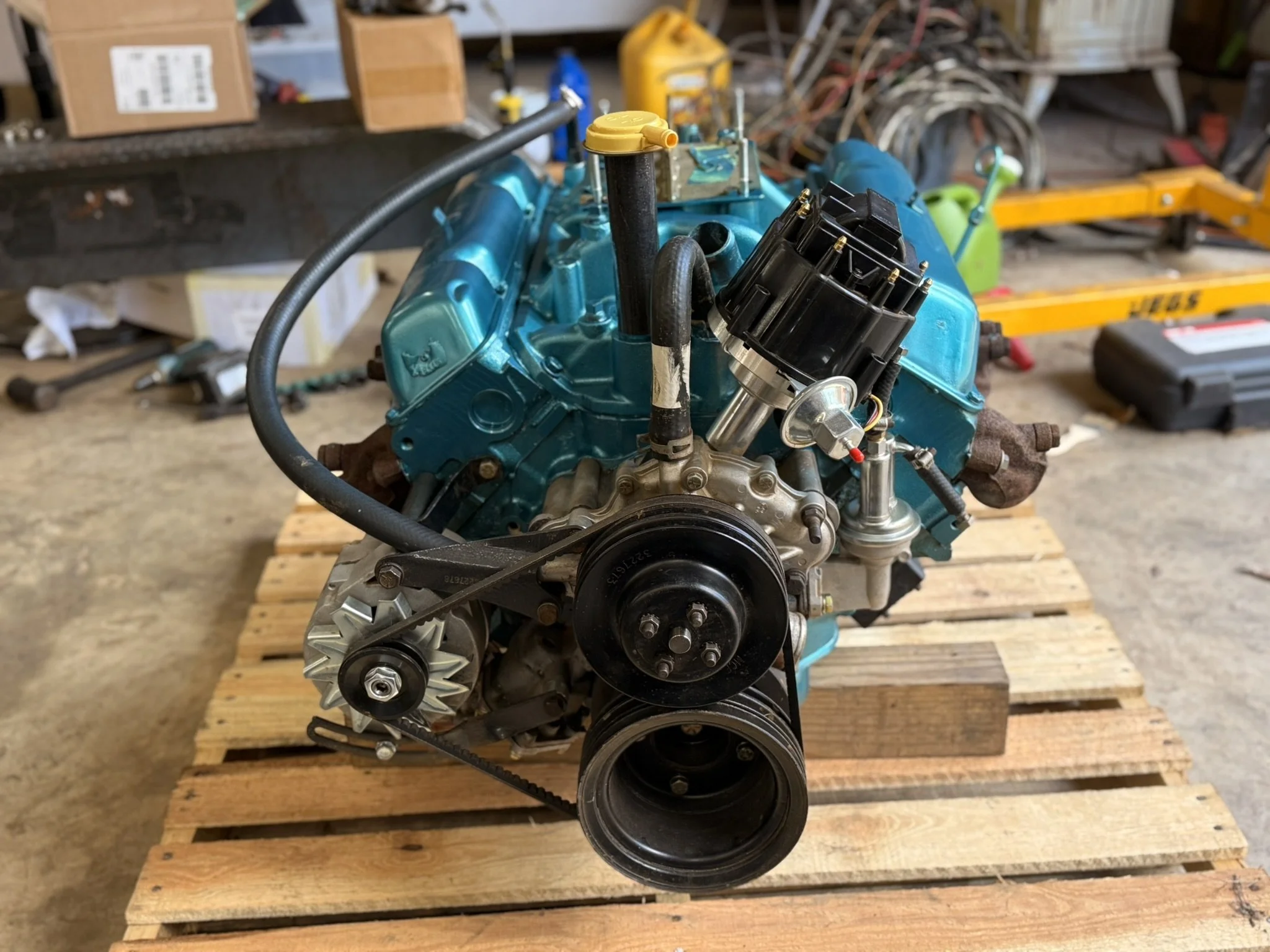

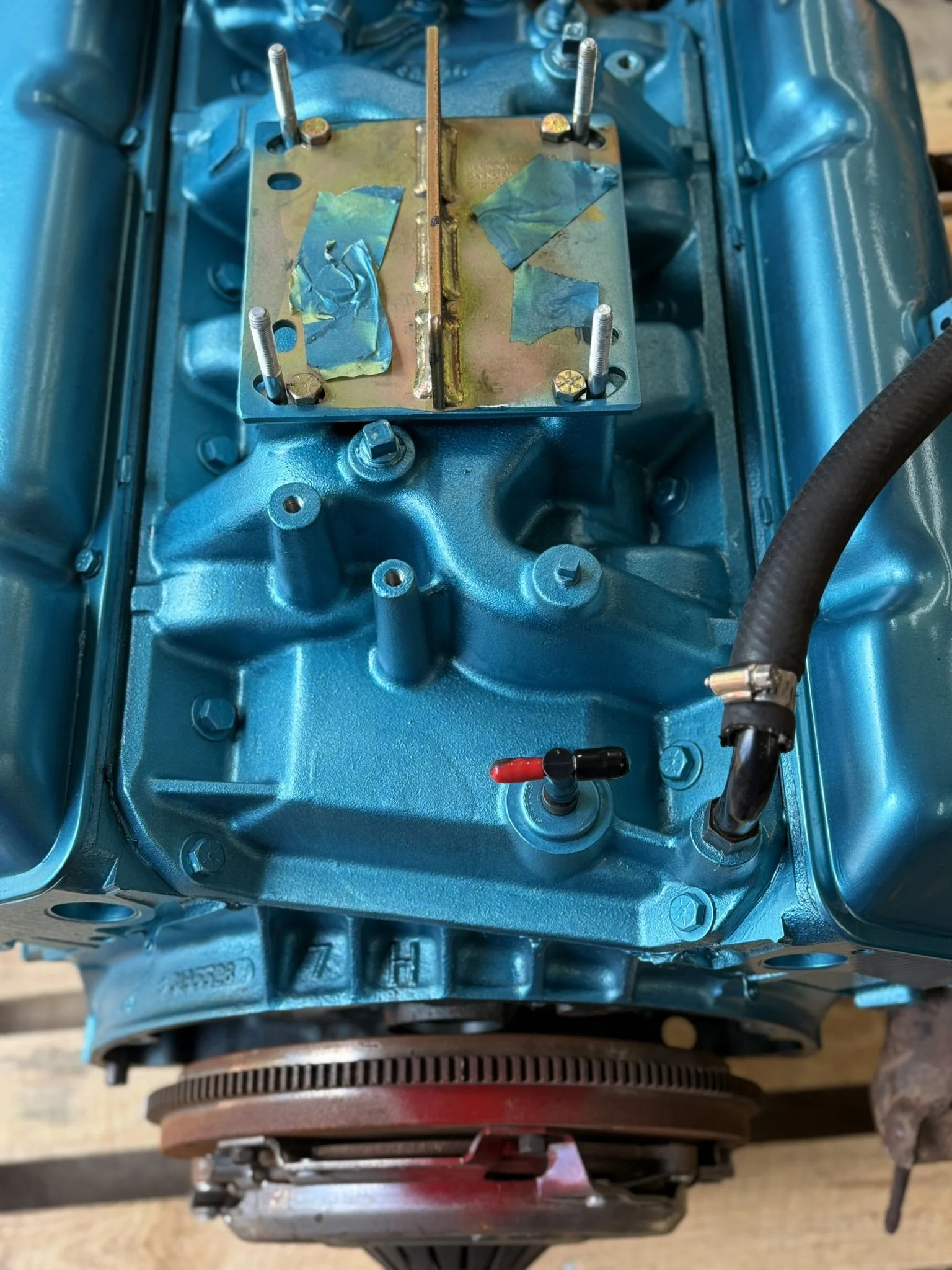

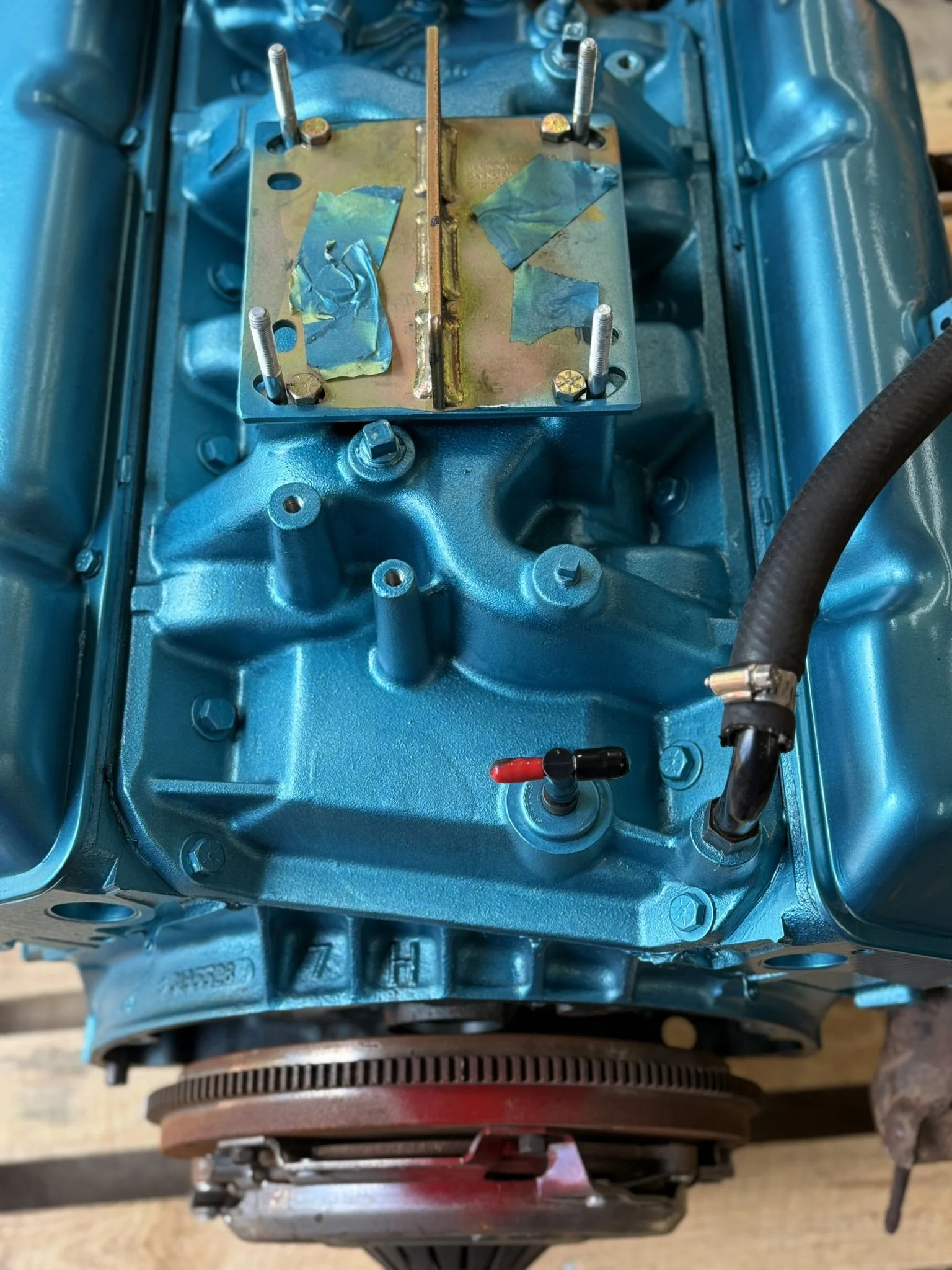

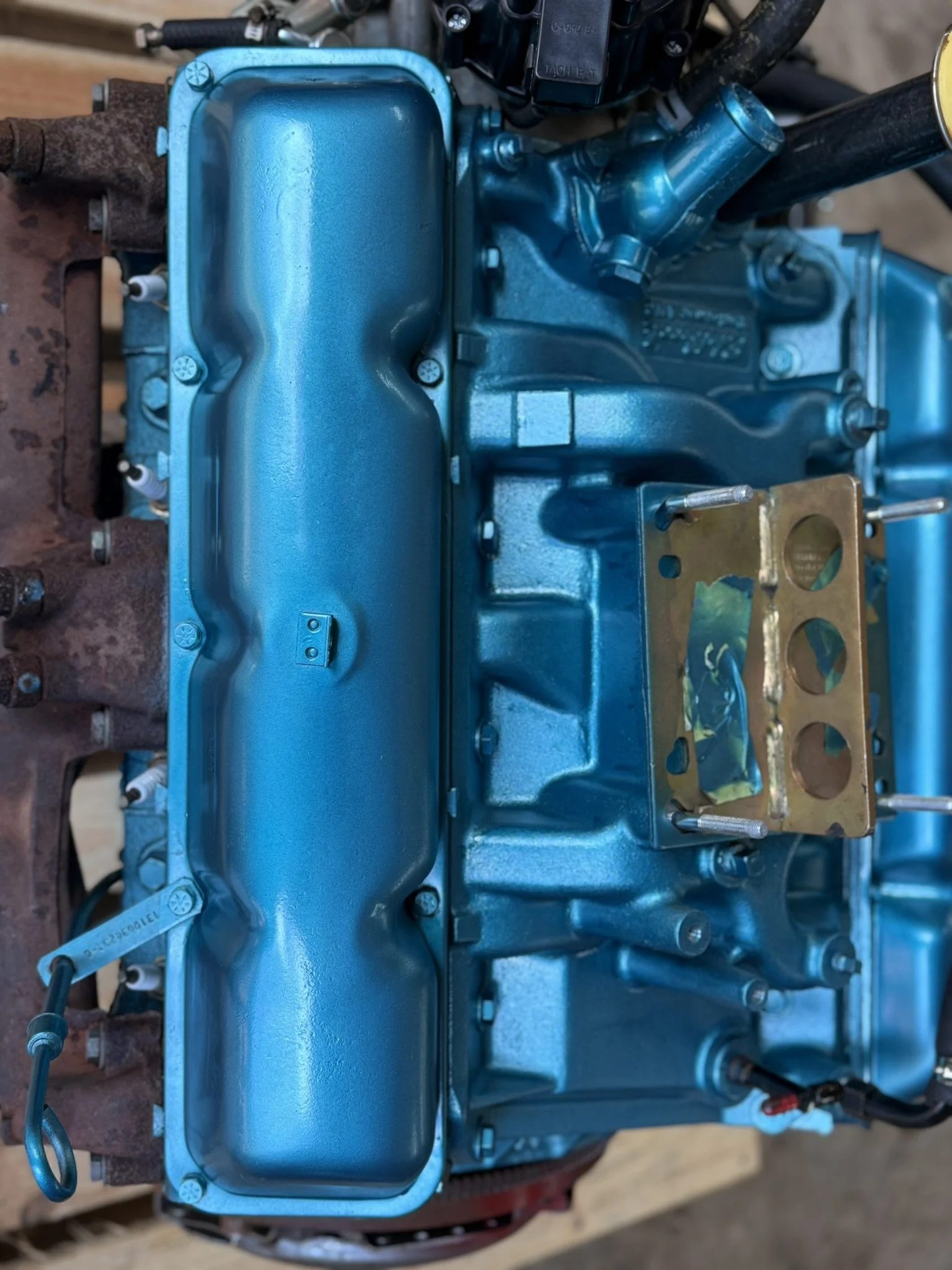

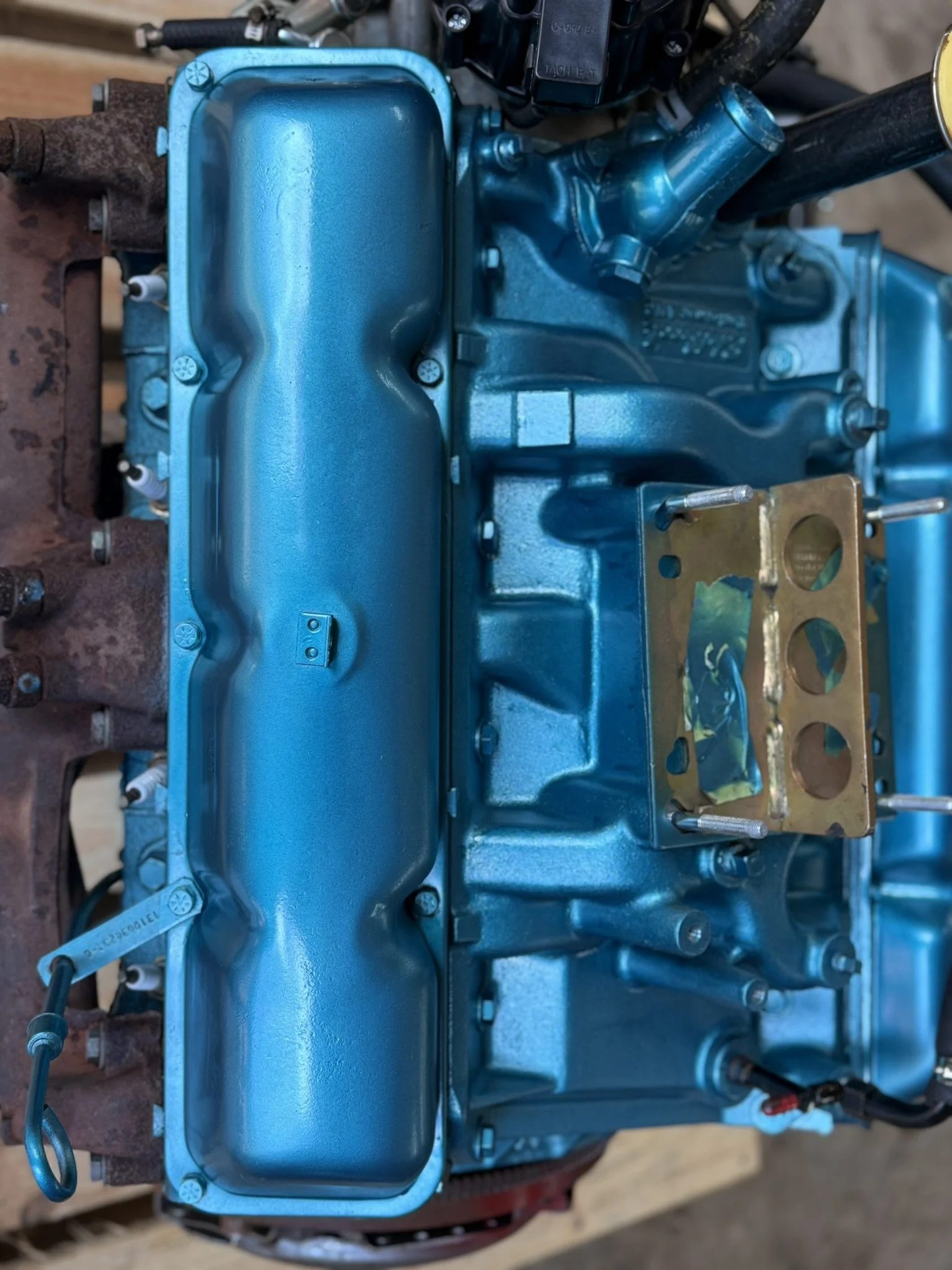

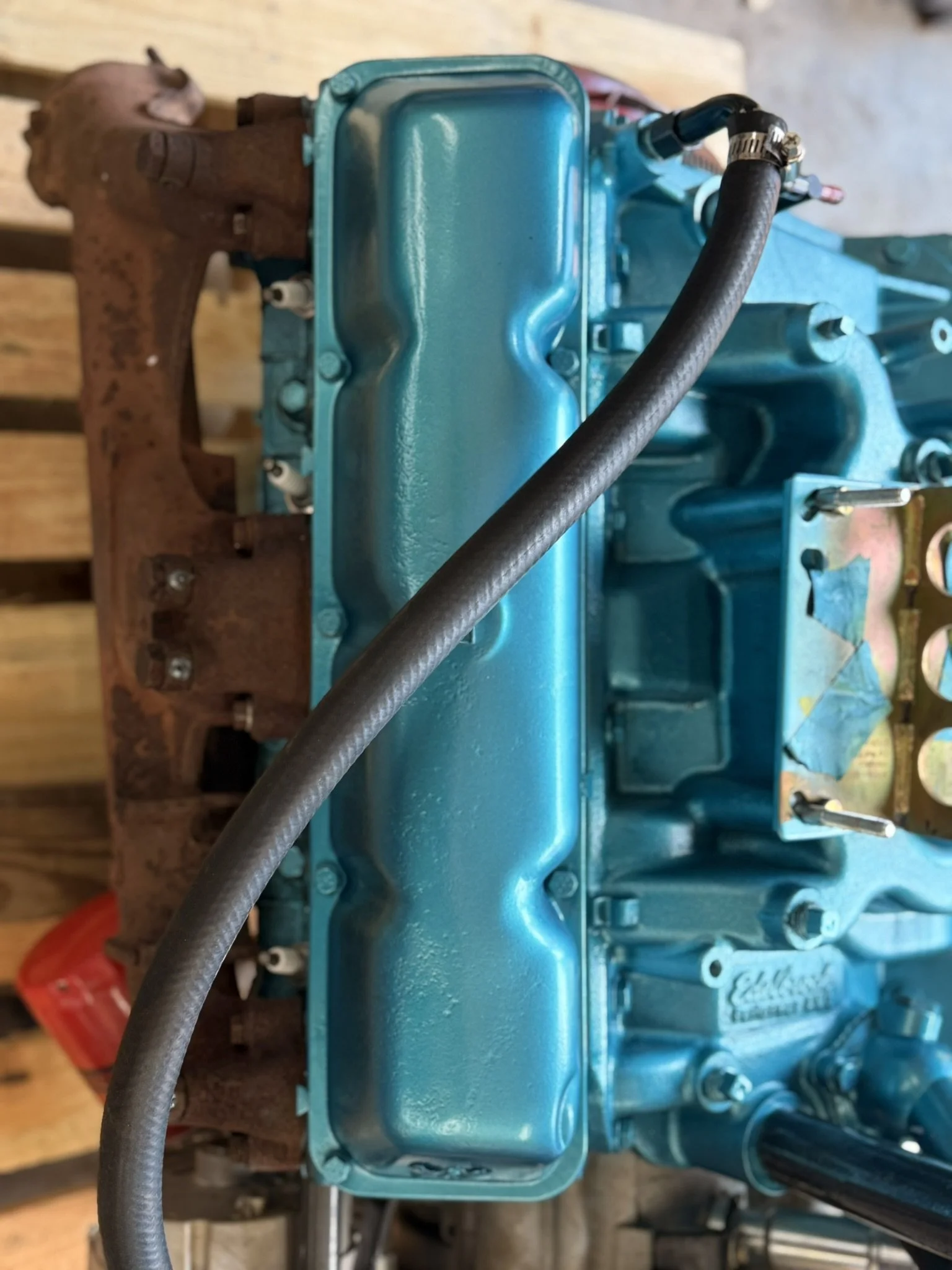

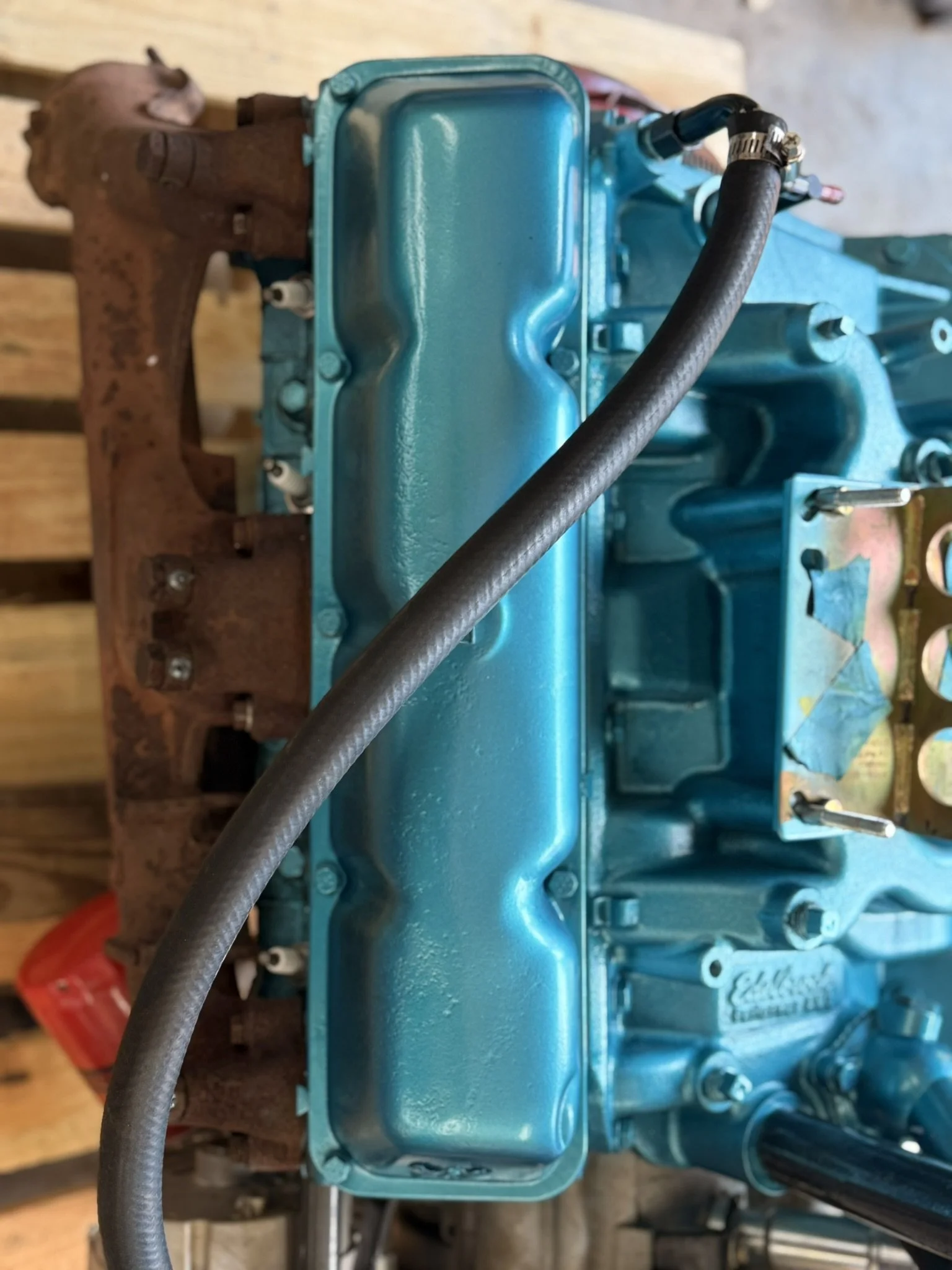

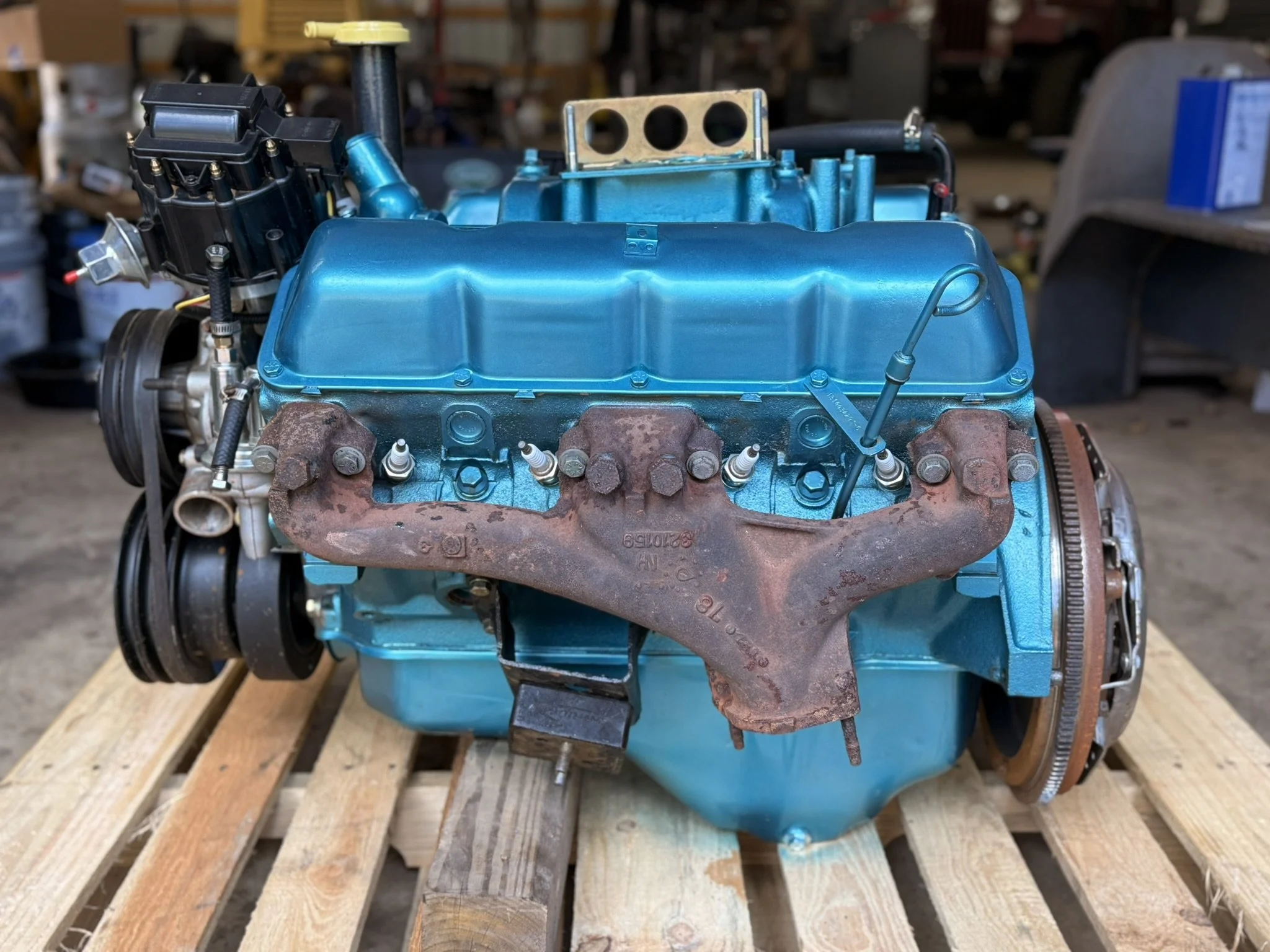

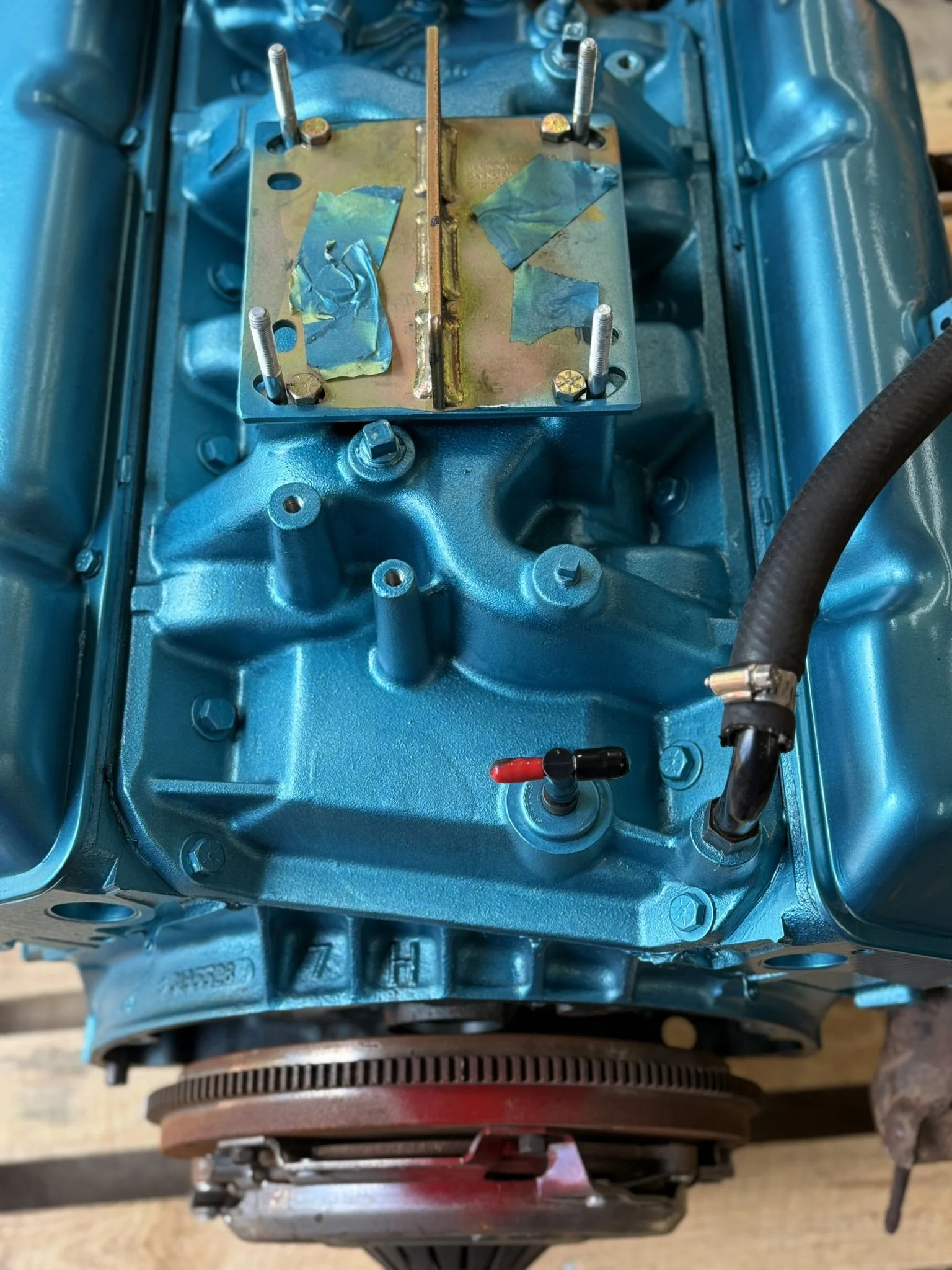

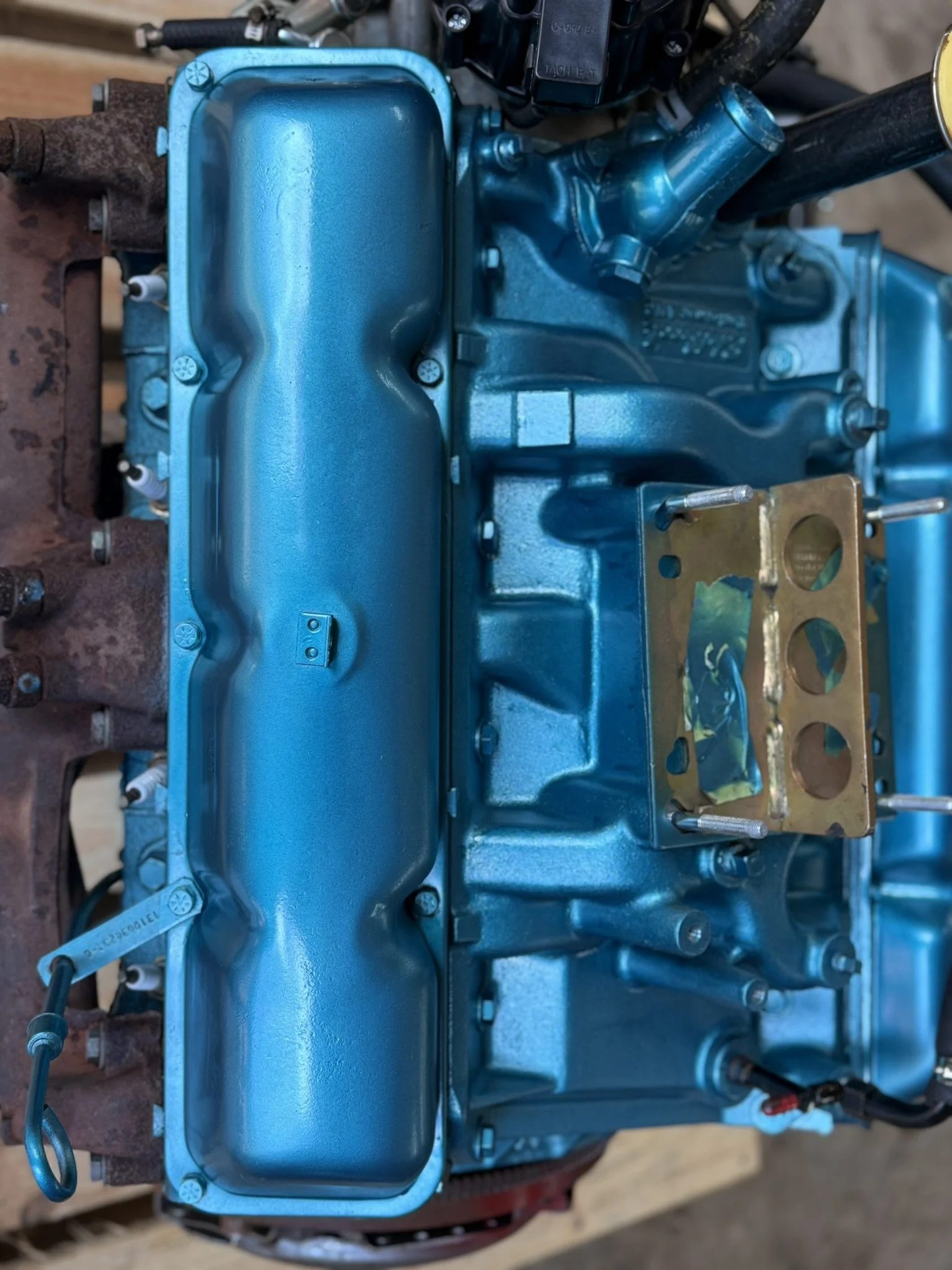

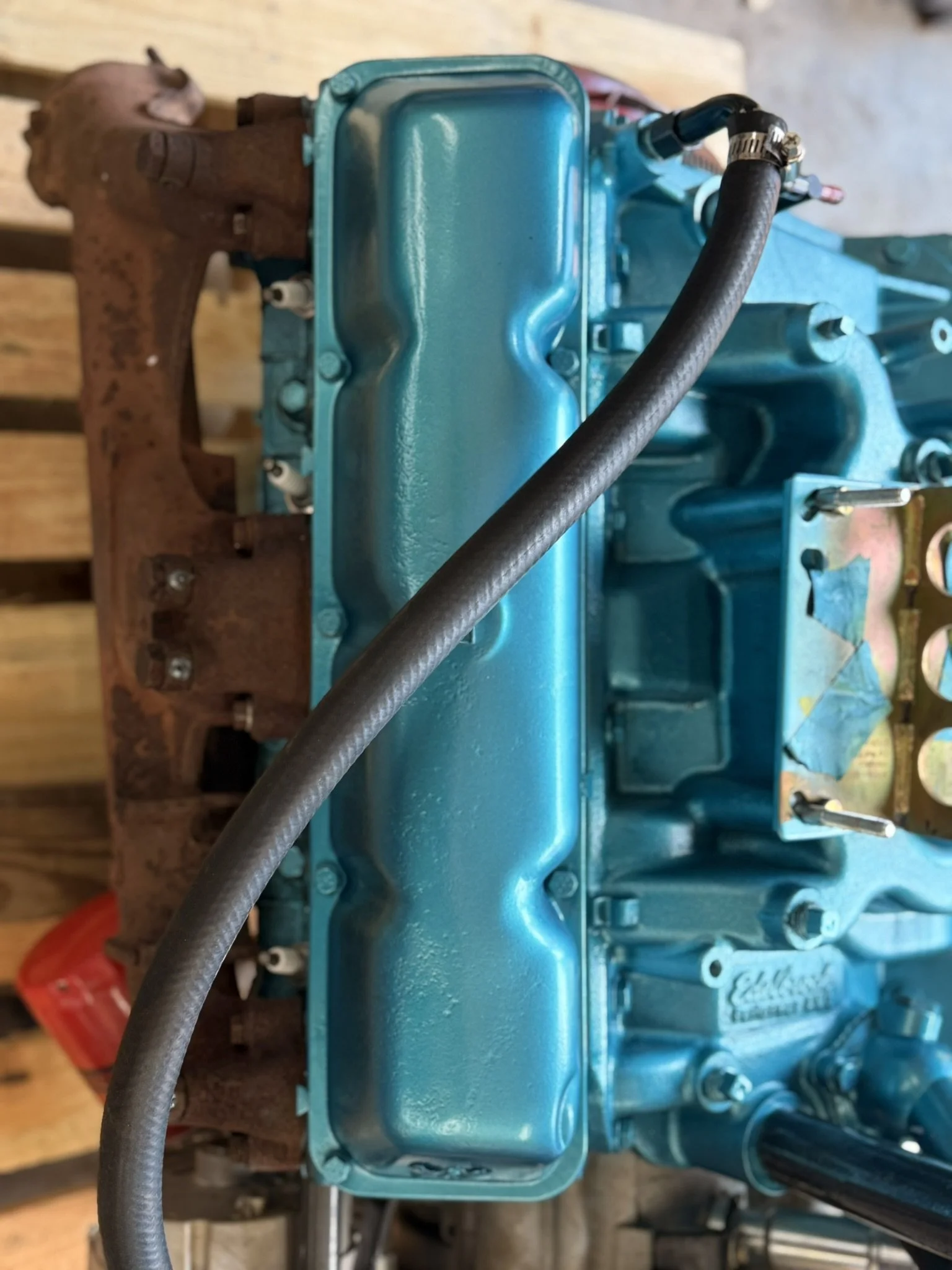

AMC 360 V8 Engine Remanufactured Ready to Run Read Description Video CAN SHIP in MD

Please read the entire description. There is a long story and build sheet with this AMC engine and the only way to get the entire picture is by studying everything below.

BACKGROUND: this engine was originally built for me and not as inventory for sale - it was going into one of my CJ projects but that project did not get going and thus this engine is now for sale. The pictures you see are from the engine you will receive minus the follow which is not included: engine mounts, exhaust manifolds, intake cover plate - everything else shown is included. This engine was installed into a spare frame to break in the cam - after successful break in the engine was then removed and moved back indoors. I take great care in my engines and the ones I build for customers or myself do not see anything spared - these details below. The most important part of these engines, the cam, has been broken in (more on this below). Purchasing any flat tappet engine (AMC or other) that hasn't had the camshaft broken in means that you will be doing the break in run and hoping the engine survives...buying this engine means the worst part is over. You simply plug this engine into your chassis, tune, and go. The best practice when breaking in an AMC engine involves setting the timing at top dead center cylinder 1 and filling the carburetor with fuel before starting...this allows the engine to instantly start and come up to speed for break in. This is what we did and no tuning at all - when you get the engine you will want to use a timing light and set timing as well as connect the vacuum advance on the distributor (this was not plumbed up for the break in because again the goal is to get the engine on and running at 2000 RPM as fast as possible and not wear down cam lobes by cranking on the starter). The carburetor was an old Holley 600 with zero tuning and only used to get the cam broken in. The carburetor is not included but I would suggest getting a Holley 600 remanufactured directly through Holley on eBay (they have an eBay store with a street demon 600 for $399...if you go offroad it is hard to beat the Offroad Avenger). These carburetors will bolt on and immediately be really close in tuning.

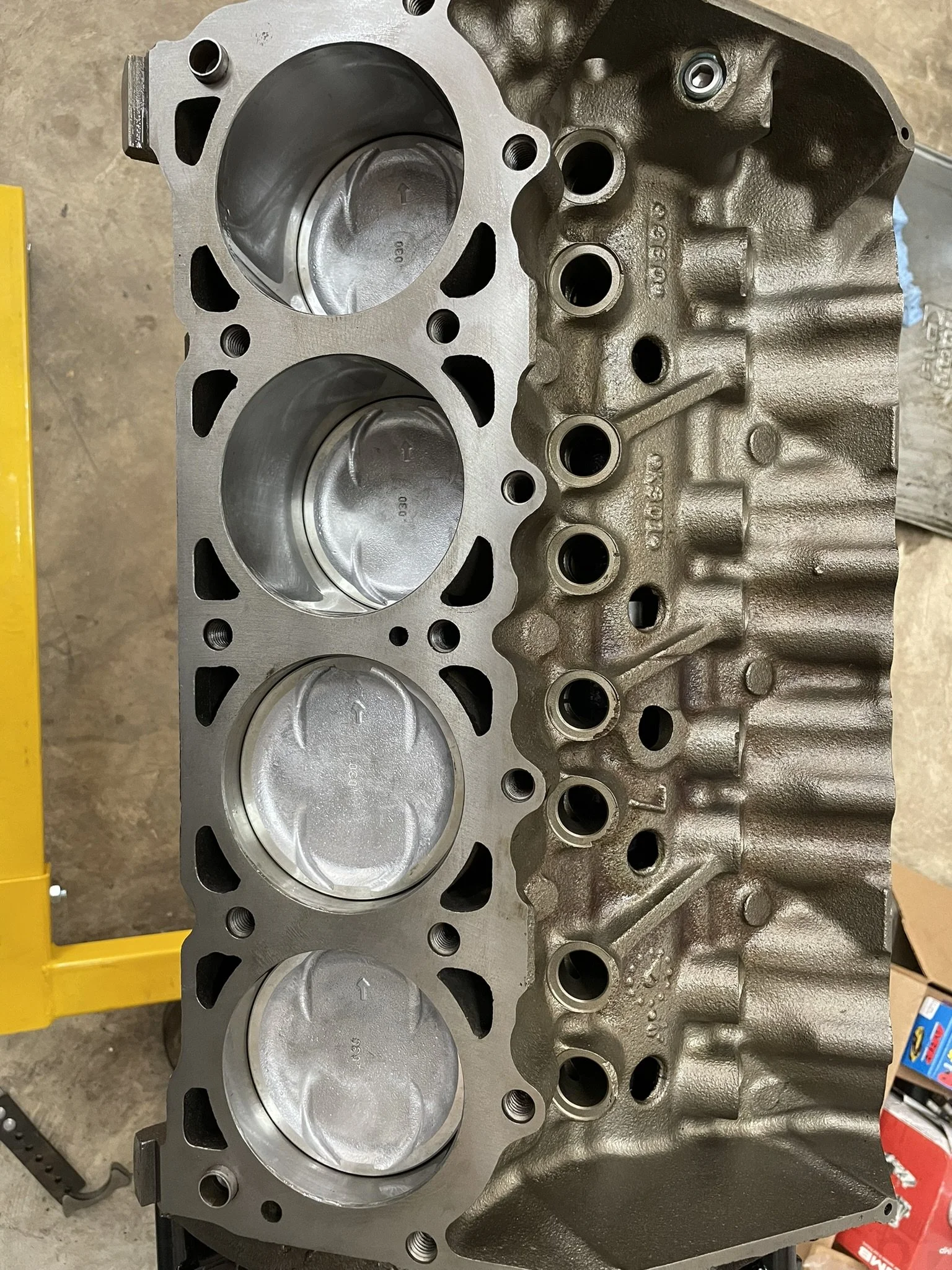

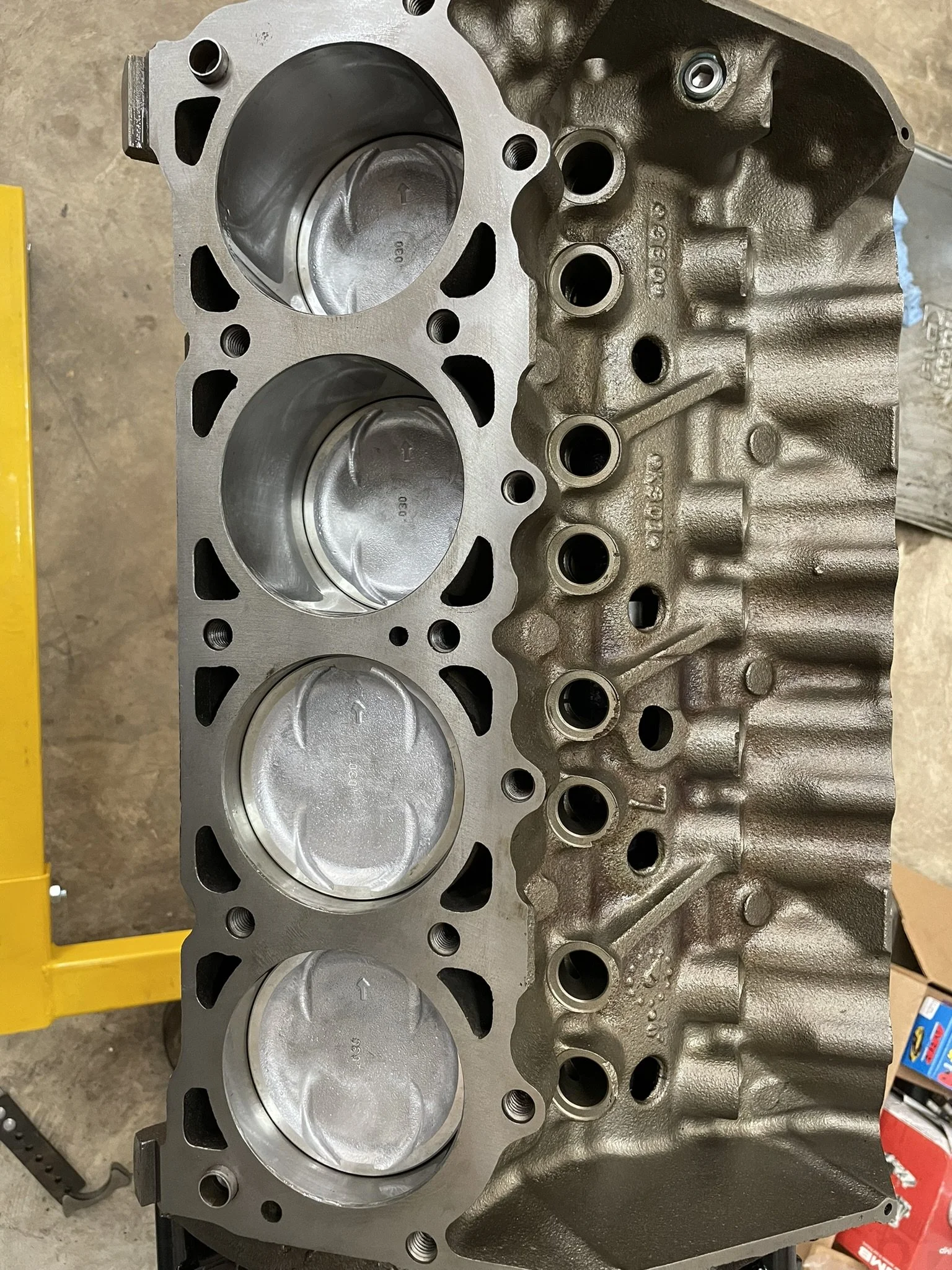

BLOCK/CRANK/RODS/PISTONS: I hunted for the best parts before committing anything to our machine shop for work. The block came from a 78 Wagoneer and thoroughly check. It was completely washed, cleaned, and shot blasted before machine work. The block was bored .030 over which brings the displacement from 360 to approximately 370 cubic inches. The blocks head surface only required 0.005 to clean up. Finding the crankshaft took time as I wanted a crankshaft that measured perfect and round without an undersize grind...I found a perfect crank that required no grinding...it polished like a gem...the crankshaft on this engine is STD/STD on the mains and rods (please see the picture of the crank after polishing). Oil clearance checked on every bearing. Rear main seal is SCE 12905. Rods resized with ARP bolts. Head bolts replaced with ARP bolts. All oiling ports and passages checked and cleaned to ensure proper flow - no under intake oil line was added nor is needed. Pistons are Silv-O-Lite cast pistons. Hastings pistons rings with plasma-moly faced top rings, phosphate-coated second rings, and an iron oil ring.

BEARINGS: all bearings were replaced with premium bearings. Cam bearings were replaced and oriented correctly for proper oil flow and pressure that reaches beyond the camshaft. No aluminum bearings were used - I exclusively used tri-metal bearings throughout.

HEADS/CAM: the stock 360 heads were shot blasted and cleaned fully before machining. All valves were replaced not reground. All guides were reamed and bronze lined. Valve seats were ground and valves were lapped in. All valve stem seals replaced with premium grade. The cam is a Melling MTA-1 grind and the springs are Melling brand double springs that match the cam. All lifters were replaced with Melling lifters. All pushrods replaced with Melling. All rockers, pivots, and bridges replaced with Melling. Each lifter bore was measured and lightly honed - all lifters were first hand spun in the lifter bores to ensure no jam on first start up. Heads only needed 0.004 milling to square them up. Head gaskets are special order 0.027 Cometic ...these give a mild bump in static compression over the thicker OE head gaskets.

INTAKE/EXHAUST MANIFOLDS: Edelbrock 2131 non-egr intake manifold (it was unpainted in the break-in video and then painted after break-in). The intake was installed with an OEM AMC PCV baffle pan attached to the bottom side of the manifold (as original). The intake manifold was not installed with castle wall gaskets (these eventually leak) and instead installed per Edelbrock instruction with castle walls sealed with 3/8" bead of gasket silicone. There is a 195 degree thermostat installed into manifold.

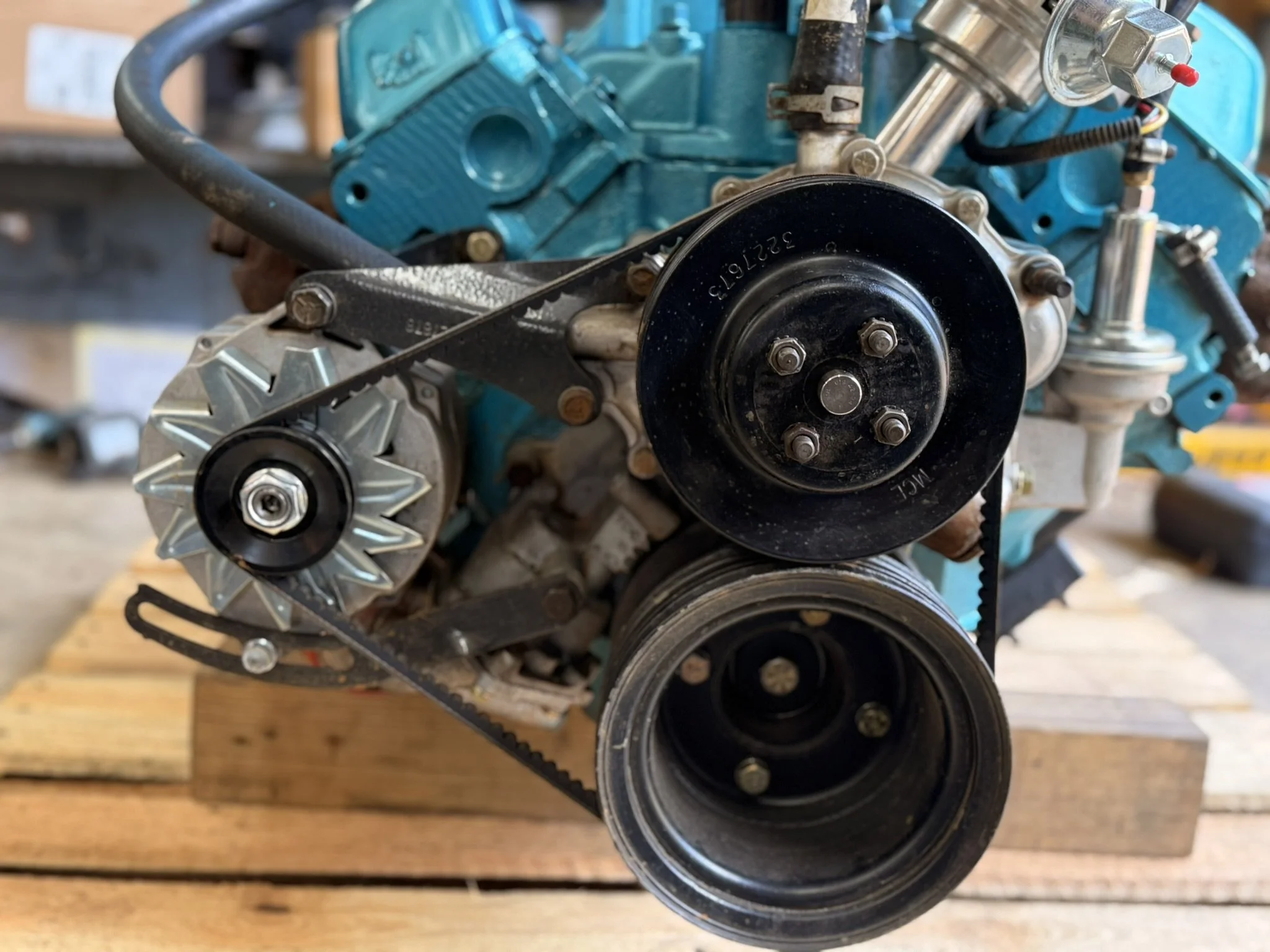

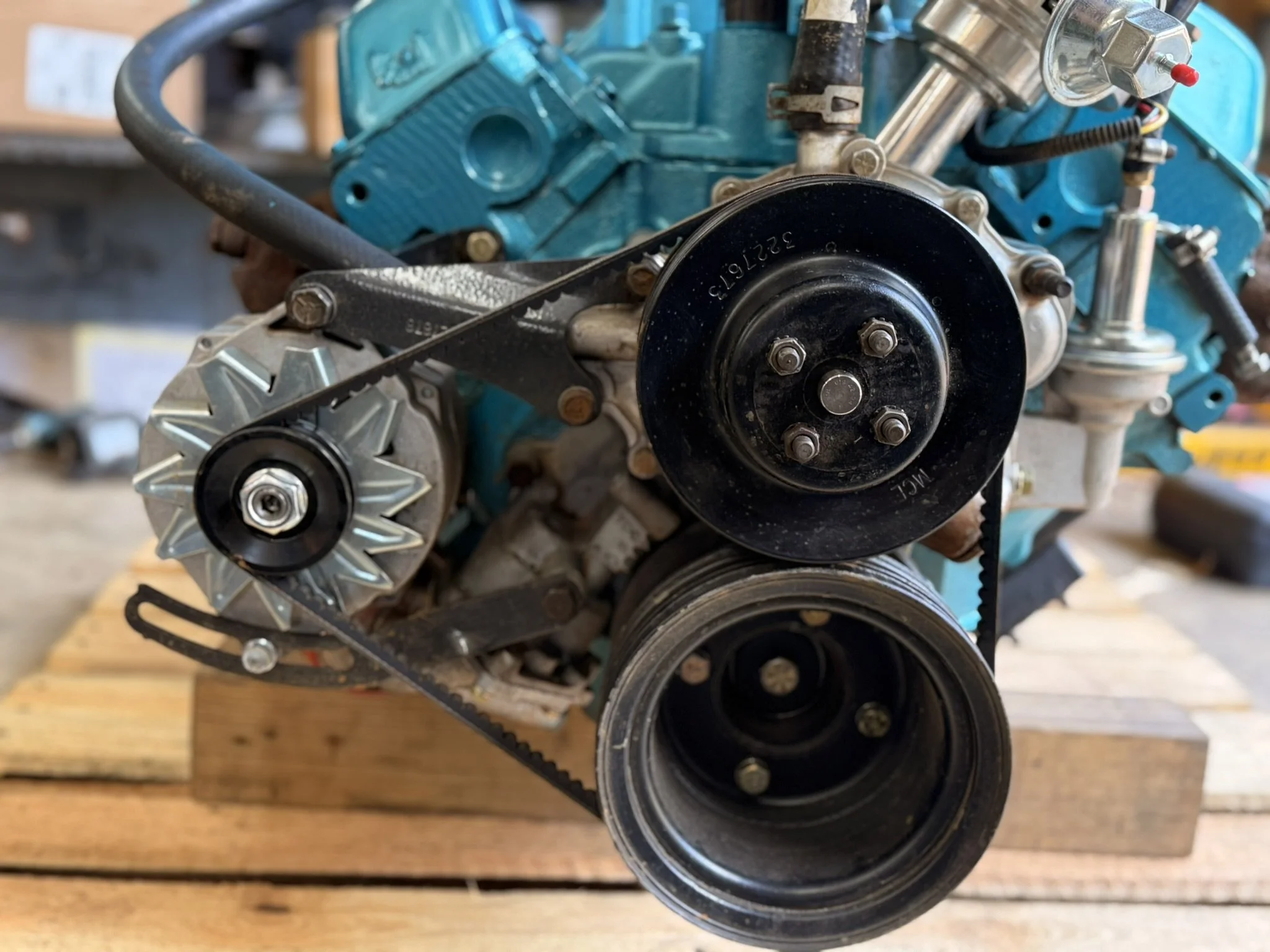

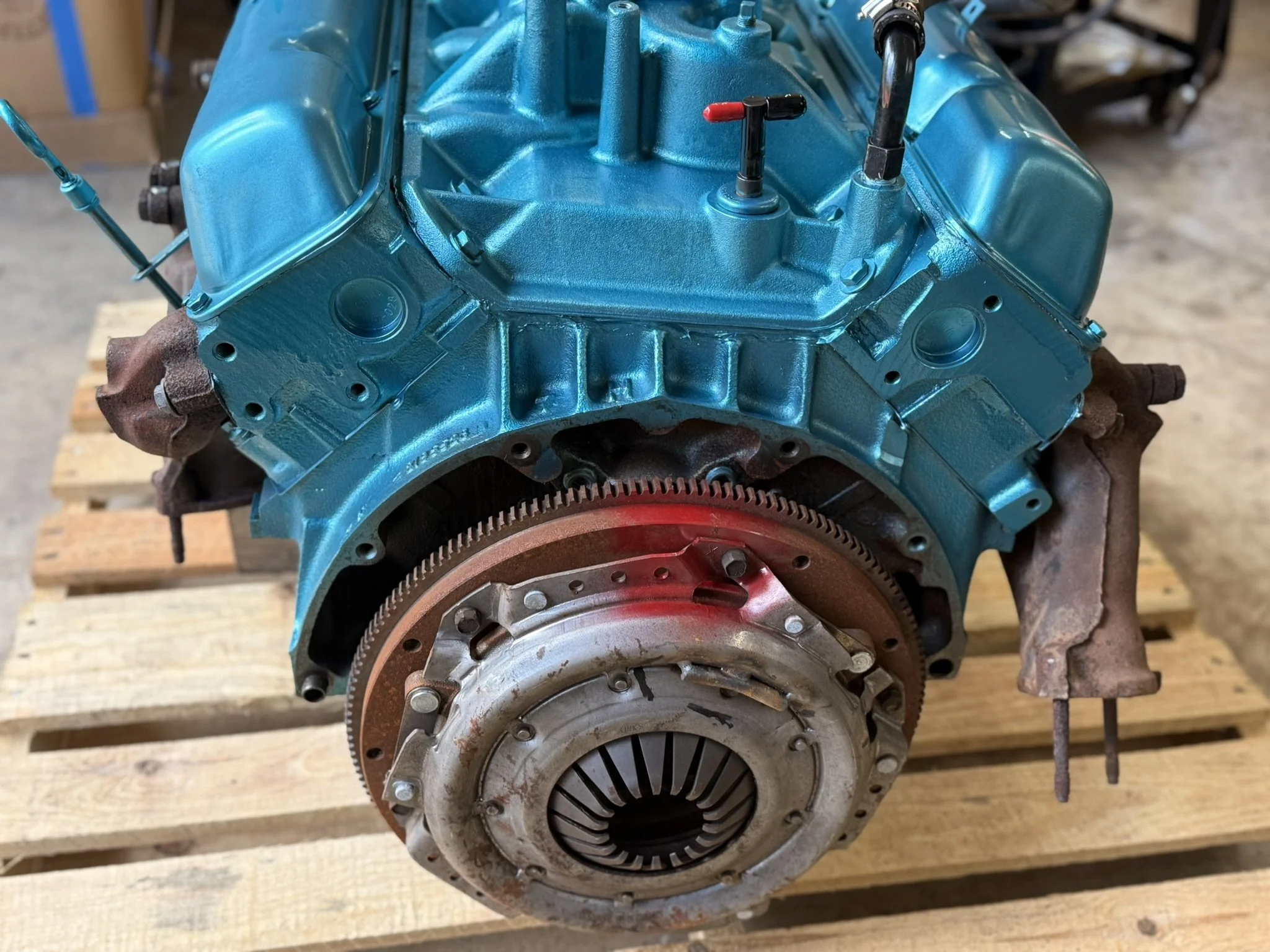

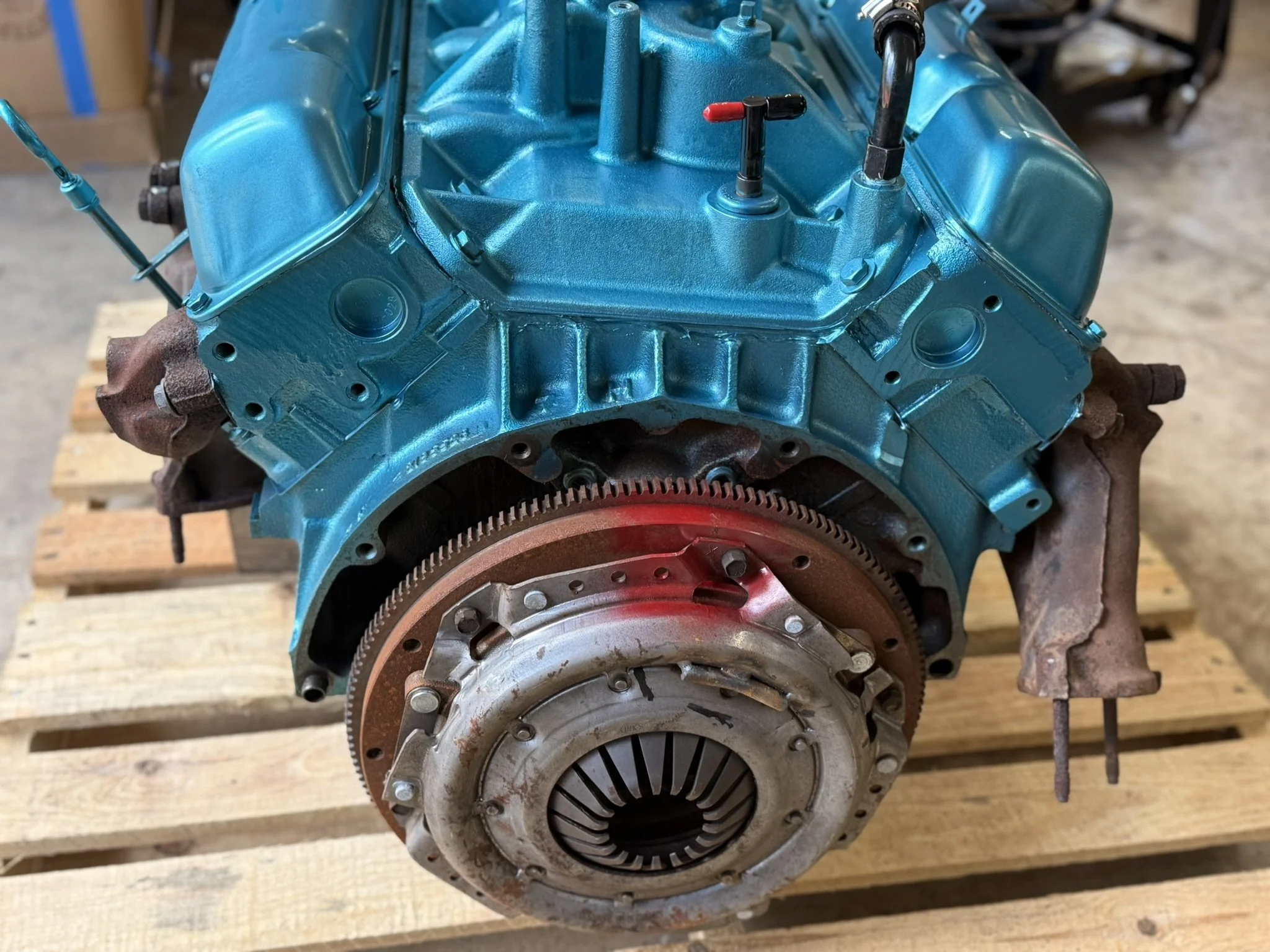

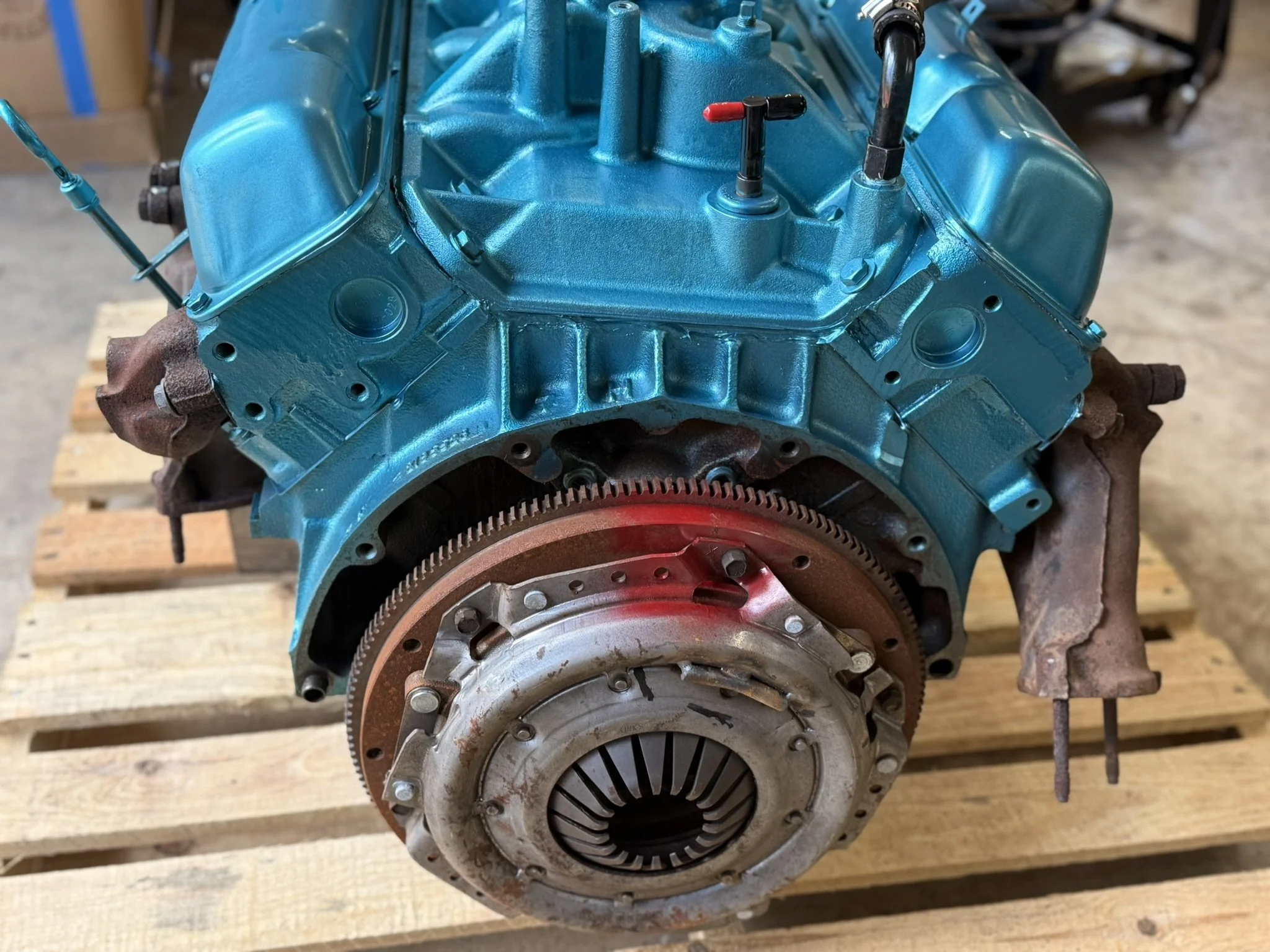

BALANCING: engine rotating assembly was fully balanced with a new balancer as well as new flywheel. The balancer came from an Australian balancer manufacturer. This engine includes the flywheel and is currently set up for a manual transmission. Along with the rotating assembly, the clutch pressure plate was also balanced. If you run a different pressure plate (currently a new LUK pressure plate for a 78 CJ7 (part 01015) or if you decide to run an automatic transmission, you will take the flywheel and pressure plate to your machinist along with your new pressure plate/clutch and have them match balanced to the flywheel clutch combo that I send you.

OIL/Water: engine was broken in with Lucas SAE 30 Break-In oil. The picture showing 50+ psi oil pressure is right after break-in and at around 1100 rpm or so. Before starting the engine the oil pump was primed and full oiling checked at every rocker. Oil was primed through the engine for at least 5 minutes before first start. The water pump is an upgraded aluminum housing pump. I installed stock studs into the water pump for a stock fan and fan clutch - the fine thread nuts will be on there for you to install your fan and clutch.

ASSEMBLY LUBRICATION: various lubricants are required for each part of the engine build. Proper cam paste was used on the cam (you can see the cam in the block covered in paste), proper assembly lubes used on all other parts. There is no 1 size fits all assembly lube and this is why this engine required 4 different assembly lubricants.

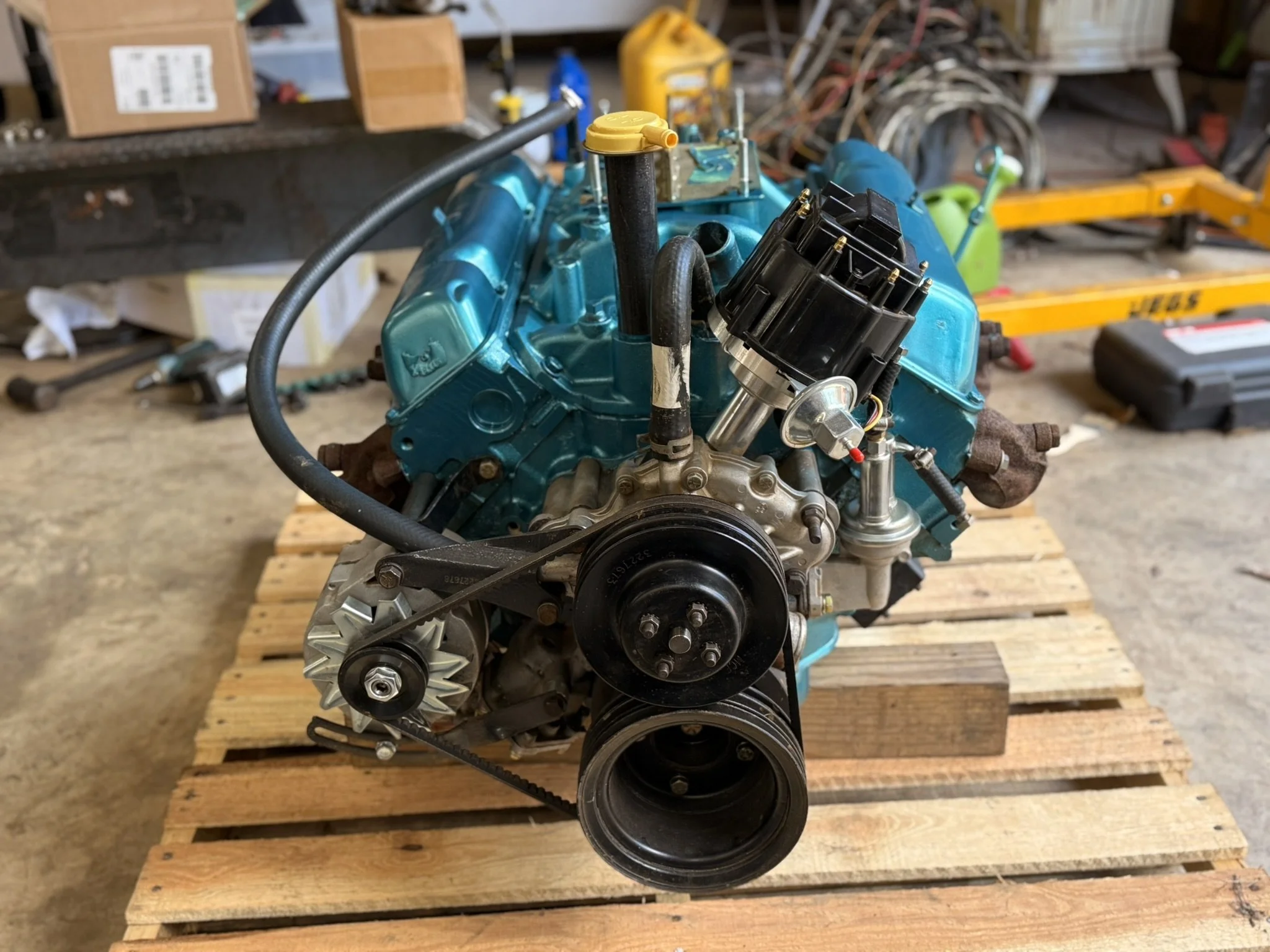

IGNITION: GM HEI with original AMC gear on distributor as well as on the cam. The distributor was checked for fit on the timing cover to ensure it is not bottoming out (this can quickly destroy the cam drive gear). The plug wires are wires we had in the shop only installed for break-in; new plug wires should be used after the engine is installed in your chassis. The GM HEI is basic and powerful. Unlike the AMC ignition, this setup sees 12V at start up and full 14.4V running. The best way to power this distributor is a 10 gauge wire to the + terminal on the cap. This wire should be fed by a relay that is triggered by the ignition turning on. A relay installation will give you maximum power at all times.

OIL PUMP: The oil pump was fully rebuilt with new gears. The idler gear was drilled to allow oil back to the idler stud. The oil pump end plate was lapped to the tighter end of AMC specification - engine holds strong oil pressure. The factory oil bypass was removed and blocked off - the oil filter stud has been replaced to allow a B2 Baldwin which has an internal filter bypass. By moving the bypass to the filter, the bypass valve will be replaced with every oil filter change and there no risk of an old bypass valve sticking in bypass. If you need an oil filter in a pinch and cannot find a B2 you can use a stock Jeep 4.0 filter from something like a 1997 Cherokee. Along with the oil pump work the engine received a new timing set. The timing set and all the various oil slots have been checked, worked, aligned so oil flows properly and particularly to the distributor drive gears.

WHAT YOU GET: on the pallet will be the engine you see from intake manifold to oil pan, pulleys back to flywheel (including pressure plate) - the . You will not receive the carburetor, bellhousing, starter, motor mount brackets, plug wires (you wouldn't want them), exhaust manifolds, or the intake cover/lift hook.

AFTER SALE: This engine will arrive ready for you to install and will require some of your stock parts to install. As you can see from the video the engine start and runs beautifully. No smoke cold or hot. It doesn't overheat. It doesn't leak. With that said you are the caretaker once it arrives. Things like a freeze plug leaking or oil leak from a seal will be something that you will have to fix and not covered by any warranty. These are things that can happen on a new engine - freeze plugs can weep for a period then stop after some running - seals could weep and sweat but eventually stop - or one of those things could need a replacement - again this is something that you would have to repair and not covered by any warranty. You will need a fresh oil filter and 5 quarts of Lucas break-in oil for another couple hundred miles of actual driving (remember the cam is broken in but the rings break in properly by having a load on the them). During this period you will drive without lugging the engine and without extended idling - RPM should be reasonable varied. After this period you will need another new oil filter and 5 quarts of a high zinc oil such as Lucas also has available (you cannot use break-in oil any longer). Doing this will keep your engine happy and living a long life. Annually change the coolant with regular green 50/50 so all the aluminum parts in the front of the engine are protected. There has been much attention to detail and only premium parts used in this engine - you do not have a warranty on this purchase because the rest of this engines life and durability is dependent on you, the buyer, to have proper installation and maintenance/tuning. With the proper care this engine will give you years and years of joy.

We can ship to you for a very low rate - we can get this to a Fastenal store or a local freight terminal for pickup. If you would like shipping please send zip code.

There is no core required and there is no core charge. This is sold outright without the need for you to send anything back.

Video After Break-in: https://www.youtube.com/watch?v=Qv8RXWfq7wU

Please read the entire description. There is a long story and build sheet with this AMC engine and the only way to get the entire picture is by studying everything below.

BACKGROUND: this engine was originally built for me and not as inventory for sale - it was going into one of my CJ projects but that project did not get going and thus this engine is now for sale. The pictures you see are from the engine you will receive minus the follow which is not included: engine mounts, exhaust manifolds, intake cover plate - everything else shown is included. This engine was installed into a spare frame to break in the cam - after successful break in the engine was then removed and moved back indoors. I take great care in my engines and the ones I build for customers or myself do not see anything spared - these details below. The most important part of these engines, the cam, has been broken in (more on this below). Purchasing any flat tappet engine (AMC or other) that hasn't had the camshaft broken in means that you will be doing the break in run and hoping the engine survives...buying this engine means the worst part is over. You simply plug this engine into your chassis, tune, and go. The best practice when breaking in an AMC engine involves setting the timing at top dead center cylinder 1 and filling the carburetor with fuel before starting...this allows the engine to instantly start and come up to speed for break in. This is what we did and no tuning at all - when you get the engine you will want to use a timing light and set timing as well as connect the vacuum advance on the distributor (this was not plumbed up for the break in because again the goal is to get the engine on and running at 2000 RPM as fast as possible and not wear down cam lobes by cranking on the starter). The carburetor was an old Holley 600 with zero tuning and only used to get the cam broken in. The carburetor is not included but I would suggest getting a Holley 600 remanufactured directly through Holley on eBay (they have an eBay store with a street demon 600 for $399...if you go offroad it is hard to beat the Offroad Avenger). These carburetors will bolt on and immediately be really close in tuning.

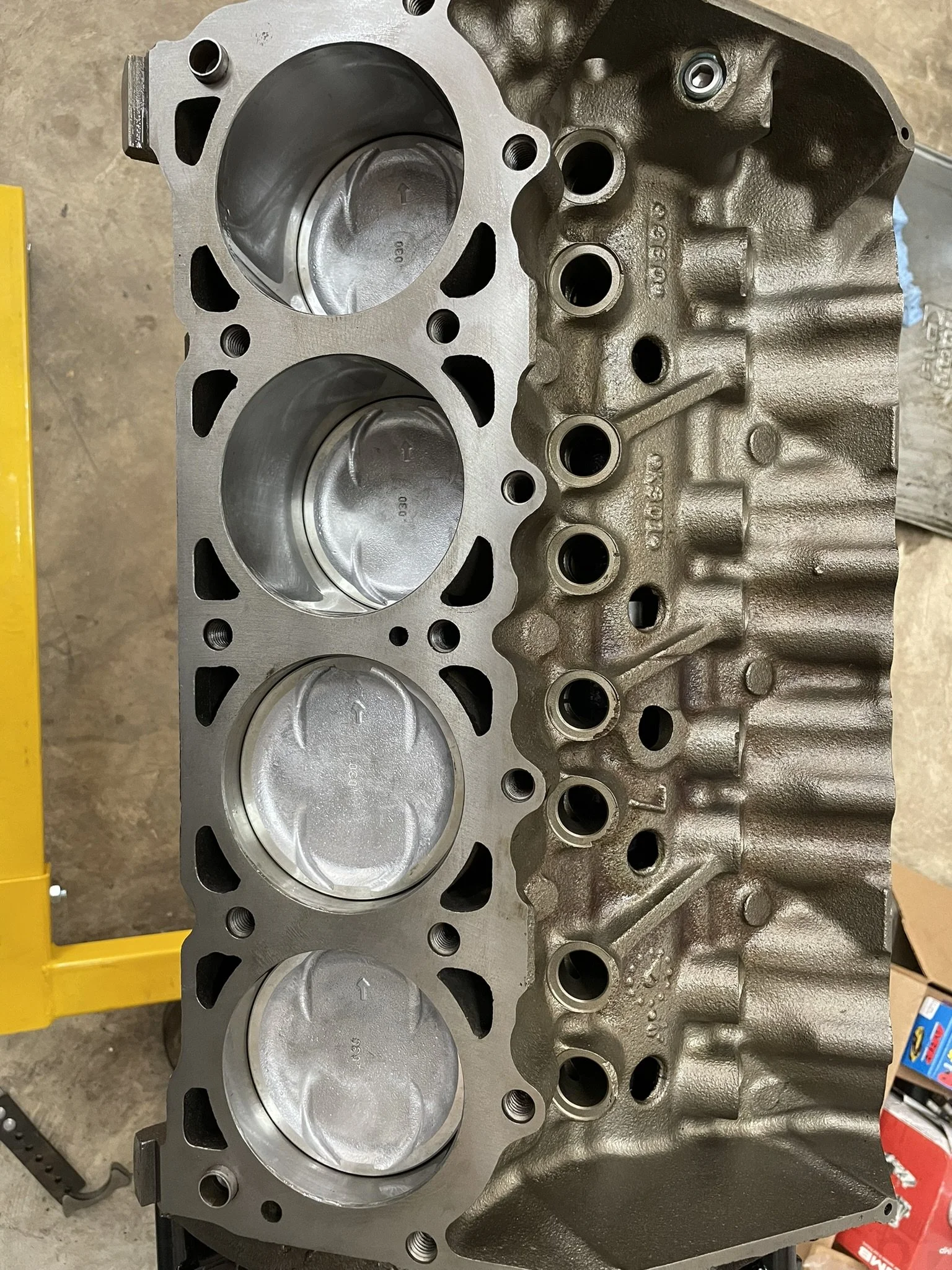

BLOCK/CRANK/RODS/PISTONS: I hunted for the best parts before committing anything to our machine shop for work. The block came from a 78 Wagoneer and thoroughly check. It was completely washed, cleaned, and shot blasted before machine work. The block was bored .030 over which brings the displacement from 360 to approximately 370 cubic inches. The blocks head surface only required 0.005 to clean up. Finding the crankshaft took time as I wanted a crankshaft that measured perfect and round without an undersize grind...I found a perfect crank that required no grinding...it polished like a gem...the crankshaft on this engine is STD/STD on the mains and rods (please see the picture of the crank after polishing). Oil clearance checked on every bearing. Rear main seal is SCE 12905. Rods resized with ARP bolts. Head bolts replaced with ARP bolts. All oiling ports and passages checked and cleaned to ensure proper flow - no under intake oil line was added nor is needed. Pistons are Silv-O-Lite cast pistons. Hastings pistons rings with plasma-moly faced top rings, phosphate-coated second rings, and an iron oil ring.

BEARINGS: all bearings were replaced with premium bearings. Cam bearings were replaced and oriented correctly for proper oil flow and pressure that reaches beyond the camshaft. No aluminum bearings were used - I exclusively used tri-metal bearings throughout.

HEADS/CAM: the stock 360 heads were shot blasted and cleaned fully before machining. All valves were replaced not reground. All guides were reamed and bronze lined. Valve seats were ground and valves were lapped in. All valve stem seals replaced with premium grade. The cam is a Melling MTA-1 grind and the springs are Melling brand double springs that match the cam. All lifters were replaced with Melling lifters. All pushrods replaced with Melling. All rockers, pivots, and bridges replaced with Melling. Each lifter bore was measured and lightly honed - all lifters were first hand spun in the lifter bores to ensure no jam on first start up. Heads only needed 0.004 milling to square them up. Head gaskets are special order 0.027 Cometic ...these give a mild bump in static compression over the thicker OE head gaskets.

INTAKE/EXHAUST MANIFOLDS: Edelbrock 2131 non-egr intake manifold (it was unpainted in the break-in video and then painted after break-in). The intake was installed with an OEM AMC PCV baffle pan attached to the bottom side of the manifold (as original). The intake manifold was not installed with castle wall gaskets (these eventually leak) and instead installed per Edelbrock instruction with castle walls sealed with 3/8" bead of gasket silicone. There is a 195 degree thermostat installed into manifold.

BALANCING: engine rotating assembly was fully balanced with a new balancer as well as new flywheel. The balancer came from an Australian balancer manufacturer. This engine includes the flywheel and is currently set up for a manual transmission. Along with the rotating assembly, the clutch pressure plate was also balanced. If you run a different pressure plate (currently a new LUK pressure plate for a 78 CJ7 (part 01015) or if you decide to run an automatic transmission, you will take the flywheel and pressure plate to your machinist along with your new pressure plate/clutch and have them match balanced to the flywheel clutch combo that I send you.

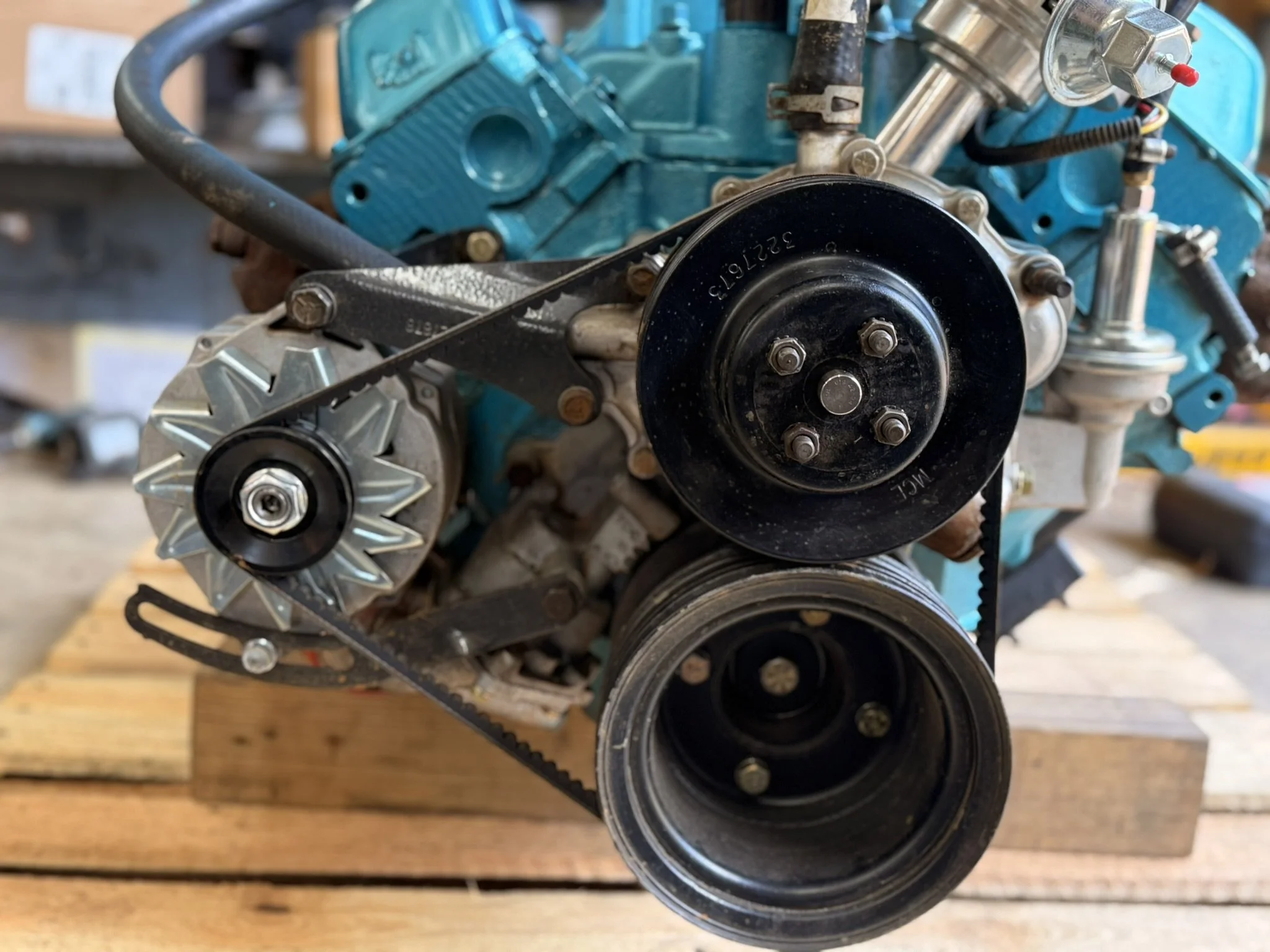

OIL/Water: engine was broken in with Lucas SAE 30 Break-In oil. The picture showing 50+ psi oil pressure is right after break-in and at around 1100 rpm or so. Before starting the engine the oil pump was primed and full oiling checked at every rocker. Oil was primed through the engine for at least 5 minutes before first start. The water pump is an upgraded aluminum housing pump. I installed stock studs into the water pump for a stock fan and fan clutch - the fine thread nuts will be on there for you to install your fan and clutch.

ASSEMBLY LUBRICATION: various lubricants are required for each part of the engine build. Proper cam paste was used on the cam (you can see the cam in the block covered in paste), proper assembly lubes used on all other parts. There is no 1 size fits all assembly lube and this is why this engine required 4 different assembly lubricants.

IGNITION: GM HEI with original AMC gear on distributor as well as on the cam. The distributor was checked for fit on the timing cover to ensure it is not bottoming out (this can quickly destroy the cam drive gear). The plug wires are wires we had in the shop only installed for break-in; new plug wires should be used after the engine is installed in your chassis. The GM HEI is basic and powerful. Unlike the AMC ignition, this setup sees 12V at start up and full 14.4V running. The best way to power this distributor is a 10 gauge wire to the + terminal on the cap. This wire should be fed by a relay that is triggered by the ignition turning on. A relay installation will give you maximum power at all times.

OIL PUMP: The oil pump was fully rebuilt with new gears. The idler gear was drilled to allow oil back to the idler stud. The oil pump end plate was lapped to the tighter end of AMC specification - engine holds strong oil pressure. The factory oil bypass was removed and blocked off - the oil filter stud has been replaced to allow a B2 Baldwin which has an internal filter bypass. By moving the bypass to the filter, the bypass valve will be replaced with every oil filter change and there no risk of an old bypass valve sticking in bypass. If you need an oil filter in a pinch and cannot find a B2 you can use a stock Jeep 4.0 filter from something like a 1997 Cherokee. Along with the oil pump work the engine received a new timing set. The timing set and all the various oil slots have been checked, worked, aligned so oil flows properly and particularly to the distributor drive gears.

WHAT YOU GET: on the pallet will be the engine you see from intake manifold to oil pan, pulleys back to flywheel (including pressure plate) - the . You will not receive the carburetor, bellhousing, starter, motor mount brackets, plug wires (you wouldn't want them), exhaust manifolds, or the intake cover/lift hook.

AFTER SALE: This engine will arrive ready for you to install and will require some of your stock parts to install. As you can see from the video the engine start and runs beautifully. No smoke cold or hot. It doesn't overheat. It doesn't leak. With that said you are the caretaker once it arrives. Things like a freeze plug leaking or oil leak from a seal will be something that you will have to fix and not covered by any warranty. These are things that can happen on a new engine - freeze plugs can weep for a period then stop after some running - seals could weep and sweat but eventually stop - or one of those things could need a replacement - again this is something that you would have to repair and not covered by any warranty. You will need a fresh oil filter and 5 quarts of Lucas break-in oil for another couple hundred miles of actual driving (remember the cam is broken in but the rings break in properly by having a load on the them). During this period you will drive without lugging the engine and without extended idling - RPM should be reasonable varied. After this period you will need another new oil filter and 5 quarts of a high zinc oil such as Lucas also has available (you cannot use break-in oil any longer). Doing this will keep your engine happy and living a long life. Annually change the coolant with regular green 50/50 so all the aluminum parts in the front of the engine are protected. There has been much attention to detail and only premium parts used in this engine - you do not have a warranty on this purchase because the rest of this engines life and durability is dependent on you, the buyer, to have proper installation and maintenance/tuning. With the proper care this engine will give you years and years of joy.

We can ship to you for a very low rate - we can get this to a Fastenal store or a local freight terminal for pickup. If you would like shipping please send zip code.

There is no core required and there is no core charge. This is sold outright without the need for you to send anything back.

Video After Break-in: https://www.youtube.com/watch?v=Qv8RXWfq7wU